Meltblown fabric production line

Key words:

Meltblown fabric production line

Classification:

- Description

-

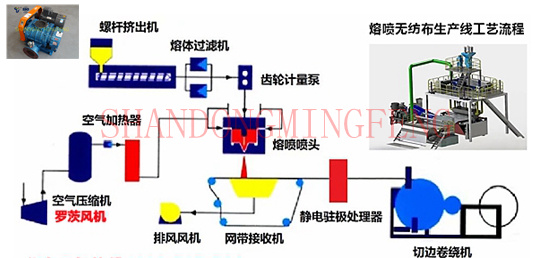

The application of Roots blowers in the meltblown fabric production lineIn the production process of meltblown non-woven fabric, the blower paired with the meltblown equipment transports plastic granules to thefeeder, and then the plastic granules (polypropylene) are melted through a screw extruder and extruded through the spinneret to becomefibrous, and under the blowing of the Roots blower at a high temperature airflow (13000m/min), they receive strong stretching, forming extremely fineshort fibers, which are adsorbed onto the net curtain. Due to the high temperature maintained after the fibers coalesce into a net, it allowsthe fibers to bond together to form meltblown non-woven fabric, which is finally rolled and packaged.The meltblown fabric production equipment mainly relies on the Roots blower to play a key role. From the meltblown fabric production process, it can be seen that the Roots blower transports plastic granules to the feeder by settingthe corresponding wind pressure and air volume, and through the melting equipment, the plastic granules are melted to form polypropylene PPspecial material, which, after plasticization, enters the meltblown die flow channel, is evenly distributed, and then enters the spinneret, where high-temperature, high-speed, high-pressure hot air is injectedto form meltblown non-woven fabric.

Related Products

Product inquiry

If you are interested in our products, please submit the following form information, we will give you a greater discount!

Submit information now to obtain the total solution of wind turbine

To provide users with high-quality products and convenient pre-sale, sale and after-sales service, reflecting the "Ming Feng" to make users satisfied with the whole process of service.

No. 1-3, West First Road North, Fenghuangshan Industrial Park, Puji Street, Zhangqiu District, Jinan City, Shandong Province

Free service hotline